Little and large at Sensor 2003 Nuremberg

Don Braggins

Sensor Review, Vol 23, Issue 4, pp. 294-298

| The Author | Don Braggins is an Associate Editor for Sensor Review. |

| Keywords | Sensors, Intelligent sensors, Size reduction. |

| Article type | Theoretical with application in practice. |

| Abstract | A sampling of new and intriguing sensing devices shown at the biennial Sensor exhibition on Nuremberg in May. Devices seen ranged from acoustic arrays several metres diameter to tiny motion sensors and Hall effect devices. Miniaturisation was a constant theme. |

|

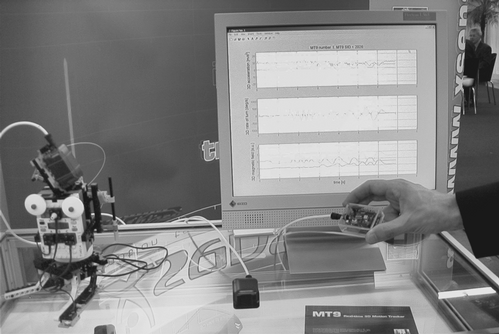

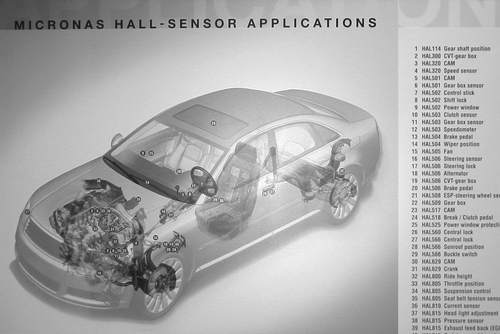

With over 700 exhibitors, it is difficult to convey the extent of this biennial Trade Fair (Sensor 2003 Nuremberg, 13-15 May 2003) which deals with all kinds of sensors and sensor systems. What follows can only give a sampling of some of the more eye-catching or intriguing exhibits on show. The most eye-catching exhibit, both from a physical point of view and from its title was the "Acoustic camera" from GfaI, Berlin. This consists of an array of microphones somewhat resembling a radar or radio telescope antenna, with a digital camera at the centre. Arrays can be from under a metre in diameter to several metres across, arranged either in concentric circles or as three arms with microphones spaced along each arm, depending on the range required. The microphone array enables the source of noise to be localised and its intensity plotted with false colour, superimposed on a regular digital image of the scene. An initially puzzling aspect of the example images was that perfectly symmetrical noise sources such as the blades of a wind turbine or helicopter rotors appeared to show asymmetric noise strengths from the tips of blades. It was explained that this is because at any one moment, one blade is "pushing" the noise towards the observer and another is "pushing" its (equal) noise in the opposite direction. For details, visit www.acoustic-camera.com; although GfaI is an Institute and as such developed the camera in partnership with several major car companies and Bosch-Siemens Household Appliances Inc., it appears to be producing the acoustic cameras on a commercial scale (Figures 1 and 2). In a huge contrast in size, the Fraunhofer Institute for Chemical Technology of Pfinztal (near Karlsruhe) was showing an insignificant looking device aimed at detecting explosives by "sniffing" extremely low concentrations, using "cyclic voltammetry" techniques. The difficulty can be seen from the fact that the vapour pressure of TNT at room temperature is about 7 parts per billion! The work is ongoing, using test concentrations down to 800 parts per trillion of TNT (checked by gas chromatography). The device will clearly have implications for airport and similar security situations. Dipl. -Ing Peter Rabenecker also pointed to the potential of the device for detecting landmines made of plastic. Tests with dogs had shown that the dog does not rely solely on smelling the explosive - the plastic casing may contribute its own vapour pressure which may be higher than that of the explosive, but equally useful for detecting mines of a consistent type. See www.ict.fraunhofer.de for Institute details. Size, or rather smallness, was a feature of the new FLIR ThermCAM E2 infrared cameras, hand-held, battery operated, with a built-in 2.5 in. colour LCD screen showing temperature at 19,200 points from a 160×120 pixel array based on FLIR Systems' latest uncooled microbolometer detector technology; the company claims that it offers excellent long wave IR imaging and measurement capability at a significantly lower cost. The E2 model can store up to 50 images in JPEG format, and its rechargeable Li-ion battery gives it a working time of about 1 1/2 h. Temperature sensitivity is quoted as 0.12°C and a built-in laser pointer allows the user to see exactly which point in the scene is the "hot-spot". Similar sized alternative versions provide accurate radiometric temperature measurement with no storage, or viewing only with no storage. Visit www.flir.com for more details (Figure 3). Size, and other characteristics, was an issue with Weinberger's high speed cameras. Some years back Weinberger commercialised developments by the Fraunhofer Institute for Integrated Circuits, Erlangen. Recently, a new smaller camera has been developed for them by PhotonFocus, the Swiss spin-off from CSEM Zurich, where their LinLog computer-controlled gamma sensor was developed initially (Figure 4). Visit www.weinbergervision.com for more details. PhotonFocus themselves were showing, in conjunction with co-workers ZMD Sensor ICs, a SVGA resolution CMOS sensor with enhanced near infrared response and a high temperature operation capability, needed for the automotive, security and surveillance industries. Although solid state sensors in general have a better NIR response than conventional vacuum tube sensors, it appears that CMOS sensors tend to fall off quite sharply just where infrared becomes reliably invisible, a disadvantage for security applications. The MV-D/A848 sensor includes the PhotonFocus LinLog capability and it also (unlike most CMOS sensors) has a "global shutter", which means that all pixels are integrating light at the same moment. This in turn means that the camera is useful for fast moving scenes, which would otherwise suffer from motion artefacts. Spectral range is quoted as 350-1,100 nm, though above about 900 nm response drops off a lot. The operating temperature range is remarkable at -40 to +125°. Visit www.photonfocus.com and www.zmd.biz for more details. Steinbichler Optotechnik GmbH is well known for its laser velocimeters and holographic interferometers for measuring vibration and deformation, but how do you apply such measurements to a rotating object such as a car tyre under test? One possibility is to use stroboscopic illumination, but this does not provide a continuous record of events. The company was showing a device which compensates for the rotation of the observed object and allows an apparently static image to be observed. Their "Rotoscan" uses a rotating prism synchronised to the rotation of the object (manually or by encoder) and a static beamsplitter, capable of following revolutions of the object up to 40,000 rpm with an accuracy of 0.1 rpm. For details, visit www.steinbichler.de (Figure 5). Here is a puzzle - how do you get three-dimensional information from a single camera? Aicon of Braunschweig had shown a two camera system the previous week at the "Control" exhibition in Sinsheim, so it was rather a surprise to see something new at Nuremburg, especially what seemed at first an impossibility. Dipl.-Ing Guenter Suilmann explained that the secret is in the fact that the system knows the exact geometry that the camera is looking at, and hence can calculate the exact location, in three dimensions, of the tip of the hand-held "target" device that is used. This is a reversal of a well developed system in which the cameras are in a hand-held pointer and look at large calibrated targets around the walls - used for tasks involving large structures such as checking bus chassis before fitting panels. See www.aicon.de and for a full description of the bus application (amongst many others) visit www.eutist-imv.com (Figure 6). Returning to theme of size, or rather, smallness, an eye-catching exhibit from Enschede in the Netherlands by Xsens Technologies b.v. was a toy robot with tiny real time motion tracking devices attached to it. The MT9 sensors are only thumb sized (39×54×28 mm) and weigh 40 g, yet can give three-dimensional readings of rate of turn, acceleration, magnetic field (earth's), and temperature, digitally at a sampling frequency of 100 Hz. The devices are aimed at human motion tracking, with applications in virtual and augmented reality, rehabilitation, ergonomics, and sports. They can be used for inertial navigation but the developers warn that the double integration needed may lead to large errors compared with the primary applications of rate of turn and acceleration. Visit www.xsens.com for more details (Figure 7). If you have a reasonably modern car, you probably know that the contact breaker has been replaced by a Hall effect device, effectively a non-contact solid-state switch actuated by a small magnet. ASIC manufacturer Micronas GmbH showed a diagram of a car with 39 other applications where such devices can be used - no single car has all of them, but each is an actual usage. They explain that, as non-contact sensing devices, Hall effect sensors are not only more reliable, but crucially they are adjustable without mechanical changes, so manufacturing tolerances can often be relaxed and adjustment is much more economic. Visit www.micronas.com for more details (Figure 8). Finally, older readers may remember the English Electric Valve Company, which became General Electric Company's EEV supplier of CCD cameras, and eventually Marconi Applied Technologies when GEC re-organised so disastrously. Following a management buyout last year, the company reverts (almost) to its earlier identity, as e2v Technologies Ltd. The company had a good presence at Sensor 2003, not only for its various specialised CCD offerings, but also for its solid state gas sensors, which at present form an important part of its business. Visit www.e2vtechnologies.com for more details. The trade fair is organised by the German trade association for sensor manufacturers, AMA Service GmbH, which also organises a special section at the annual Hannover Messe. The Nuremburg Sensor fair is not only a showcase for commercial suppliers, but also it has many composite exhibits from geographical groups of Universities and various Institutes, showing not only what is on offer at present but also what might be available in the future. Visit www.sensorfairs.de for more details (Figure 9). Sensor Review |

Figure 1 Several acoustic cameras, including the lower two arms of a large three-armed one, are shown

Figure 2 Noise from a wind generator's blades is localised

Figure 3 The new, small, battery powered IR camera from FLIR

Figure 4 The new, smaller high speed camera from Weinberger compared with its longer established, larger equivalent

Figure 5 The spinning disc on the right is imaged as stationary

Figure 6 The new "pointer with targets" is located in three dimensions with a single camera

Figure 7 The miniaturised motion tracker from Xsens

Figure 8 Forty places in a car where Hall sensors are used, though not all in the same car

Figure 9 A showcase for University research projects with commercialisation potential |